Technologies We Use for Custom Rotary Die Design

ICD integrates proven design principles, sensor readiness, and materials engineering to produce high-precision dies built for your exact application.

Anti-Bounce Design Principles (US 11,292,146 B2)

Places pressure cylinders optimally to minimize bounce at speed and ensure consistent cut depth.

Laser-Driven Bounce Detection Integration

Designs are sensor-ready and validated with bounce data to protect blades and maintain precision.

Engineered Edge Materials for Durability

We specify tungsten-carbide, powdered-metal, or other edge materials matched to your web, abrasiveness, and run speeds.

Let us design a smarter die that lasts longer, runs cleaner, and adapts to your bonding or lamination processes.

Design Capabilities & Specifications

Maxcess and ICD offer unmatched flexibility in die construction, tailored to your unique converting line:

| Capability | Spec (US / Metric) |

|---|---|

| Roll Diameter | Up to 26″ / 660 mm |

| Pattern Width | Up to 50″ / 1 270 mm |

| Overall Die Length | Up to 125″ / 3 175 mm |

| Die Materials | Tungsten-Carbide, Powdered-Metal, Tool Steel |

| Bonding Support | Ultrasonic, Thermal, Pressure, Elastic Entrapment |

| Tolerances | Ultra-tight, material-specific edge profiles |

Applications We Support

Whether you’re launching a new product or fine-tuning a complex converting line, we design dies for a wide range of industries or materials.

Flexible Packaging

High-speed dies engineered for thin films, laminates, and multi-layer substrates.

Nonwovens

Custom solutions that deliver clean, consistent cuts for hygiene, medical, and filtration projects.

Specialty Labels

We support custom die needs for prime and functional labels, from micro-perforations to unique contour cuts.

Foam, Film & Foil Processing

Robust dies are designed to handle compression, static buildup, and complex material stacks without sacrificing accuracy.

Automotive Films

Laminates, sound-dampening pads, wire-harness tapes.

Electronic Tapes

EMI/RFI shielding, thermal interface pads, optical films.

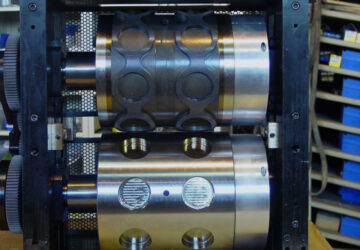

Supported Tooling Configurations

Our custom die design services extend to all common rotary die types and machine configurations, including:

- Window Dies

- Patch Gummers

- Profile, Separating, or Patch Knives

- Tape Cylinders

- Score Shafts

- Gears & Coupling

- Bearing Blocks

- Custom Converting Components

Not sure which material fits your run volume?

Our Design Process

We combine hands-on engineering consultation with cutting-edge modeling and prototyping to ensure the die you get is exactly what you need.

Consultation & Feasibility

We start by understanding your material stack, tolerances, product specs, and line setup. This allows us to assess feasibility and recommend the most effective die architecture.

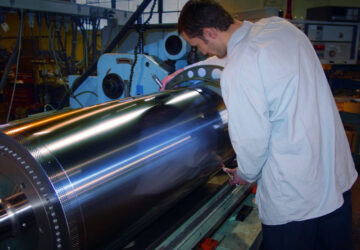

CAD Modeling & Prototyping

Our team creates detailed CAD models and can provide physical prototypes or test cuts upon request, reducing development risk and ensuring performance before production.

Final Design & Fabrication

Once approved, your custom die is precision-manufactured using ICD’s proven fabrication techniques, backed by Maxcess’s service and support infrastructure.

Additional ICD Services

Pair your die design with services that validate performance, implement upgrades, and certify compliance

Die Rebuilding & Repair

Restore edge geometry and extend die life; apply bounce‑reducing upgrades where appropriate.

Die Quality Assurance

Inspection, measurement, and documentation to verify specs and meet regulatory/customer requirements.

Die Product Evaluation

Diagnose wear, misalignment, and performance risks before they impact yield.

Already Using a Die? We Can Reverse Engineer It

If you’re looking to improve or replace an existing die, we offer complete evaluation and reverse engineering services to replicate, enhance, or reimagine your current tooling with more innovative design and better materials. Want to upgrade during the redesign? We can spec ICD anti-bounce or bonding-friendly die features into your new tooling.

ICD’s Legacy of Design Excellence

With over 40 years of rotary die innovation, International Cutting Die has earned its place as a trusted partner in precision converting. Now as part of Maxcess, ICD’s custom dies continue to set the industry benchmark for quality, longevity, and support.

Why Choose ICD-Engineered Dies?

- Price: Competitive design-to-value ratio

- Quality: Precision materials and proven performance

- Service: Expert consultation, support, and turnaround

Contact International Cutting Die

Let’s Design Your Next Advantage

Your converting line deserves more than a standard die. Let’s build a better solution together, engineered to solve real problems and deliver measurable performance.