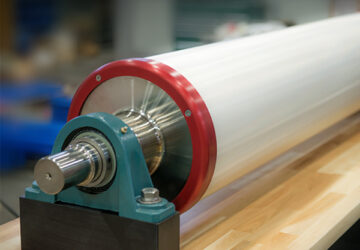

Mill-Duty Leaf Shafts

Ideal for robust applications like metals processing and paper reels

Leaf-style design delivers more winding surface and is best for eliminating core deformation

Durable construction designed to withstand abuse and abrasion

Mill-Duty Leaf Shafts Overview

The Tidland Mill-Duty Leaf Shaft is designed for heavy-duty 178 mm to 610 mm (7 in to 24 in) ID cores, as well as coreless operations. The largest diameter leaf shaft available, this shaft is excellent for tougher jobs such as winding metal and foil strips. It can also be used as a reel spool for paper reels and large paper machines. These leaf shafts provide successful roll control and elimination of thin wall core deformation. With 360-degree radial expanding grip along the entire leaf face, the Series 750 delivers more winding surface and allows for the winding of single or multiple rolls, with or without cores.

*Approximate Torque Capacity

Mill-Duty Leaf Shafts - Torque Capacities per Nominal Core Size*

| Nominal Core Size | 8.00 in203.2 mm |

|---|---|

| Fiber Core | 461 lb-in461 lb-in |

| Steel Core | 304 lb-in304 lb-in |

| Nominal Core Size | 10.00 in254 mm |

| Fiber Core | 671 lb-in671 lb-in |

| Steel Core | 443 lb-in443 lb-in |

| Nominal Core Size | 12.00 in304.8 mm |

| Fiber Core | 1,107 lb-in1,107 lb-in |

| Steel Core | 731 lb-in731 lb-in |

| Nominal Core Size | 16.00 in406.4 mm |

| Fiber Core | 1,476 lb-in1,476 lb-in |

| Steel Core | 974 lb-in974 lb-in |

| Nominal Core Size | 24.00 in609.6 mm |

| Fiber Core | 2,952 lb-in2,952 lb-in |

| Steel Core | 1,948 lb-in1,948 lb-in |

User Manuals

- Cardboard

- Flexible Packaging

- Food and Beverage

- Packaging

- Pharmaceutical

- Specialty Converting

- Tag and Label

Related Products

Kantiroller

This innovative steering guide delivers precise web or strip position by bending the web through a long entering span, providing immediate lateral correction for transient errors while also compensating for the web or strip steady-state errors.

Tidland Reel Spools

The Series 860 is a heavy-duty air shaft designed for maximum reliability and performance in demanding mill environments, reducing the cost and storage of expensive reel spool mandrels. The ergonomic design also provides increased safety, eliminating the need for locking collars or wrenches.

GTS Load Cells

MAGPOWR’s GTS Global Load Cell ensures stability and accuracy, allowing tension to be precisely measured and controlled on a roll.

Vacuum Tension Rolls

A uniquely engineered internal vacuum system provides a strong, stable grip on a variety of materials, ensuring consistent and reliable web handling.