Tidland SmartSlit™ – Automated Slitting System

Enhance Operator Safety & Cut Setup Time with the Tidland SmartSlit System

- Multiple slitting configurations, including shear, crush, and razor

- Repeatable setup when switching materials

- Dust-tight sealed linear actuators for top and bottom knife manipulators

- Blade positioning software enables customized slit positions, pattern saving, individual or group knife adjustment, and optional manual adjustment

- Save time and reduce errors by storing repeat jobs/patterns for reuse

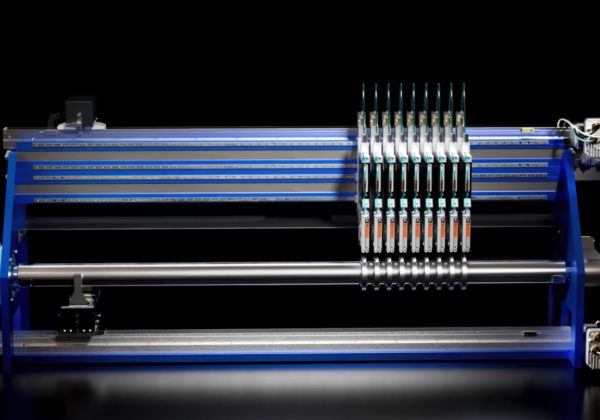

Introducing the Tidland SmartSlit™ System

The Tidland SmartSlit™ system is the premier automation solution for narrow web applications. Its automated machinery movement minimizes manual adjustments, reducing operator errors and boosting efficiency. Operators can also make manual slit adjustments on the fly when needed, offering flexibility. With built-in software integration, the system ensures precise, automatic placement of slitting blades, significantly cutting down setup time and eliminating manual calibration. The Tidland SmartSlit Automated Slitting System is designed to streamline production processes by delivering precise and efficient cuts. For converters in the flexible packaging industry, the SmartSlit is particularly suited to handle the demands of flexible packaging solutions, ensuring precise and efficient slitting, even at high speeds.

Why Choose Tidland SmartSlit™?

Available in shear, crush, and razor configurations, the Tidland SmartSlit™ offers a safe, user-friendly approach to slitting operations. The system pays for itself in less than two years when compared to manual systems, outperforming the closest competitor. With SmartSlit™, your company can greatly enhance efficiency while cutting operational costs.

Applications

To install the Tidland SmartSlit™, application engineering services are required to determine the system’s fit. System measurement services are available for those needing assistance. We recommend scheduling a one-day Installation and Training service, which includes installation, calibration, and system training. If necessary, extended group training is also available. If you need assistance with the SmartSlit system, our technical support team is available to help with troubleshooting and maintenance.

- Max Slit Width: 48” (1220mm)

- Inside Frame Width: Max Slit Width + 4.6 in (116.84mm)

- Outside Frame Width: Max Slit Width + 6.2 in (156.1mm)

- Minimum Slit Width: .78 in (20mm)*

- *using Advantage Series Knifeholders

- Maximum # of Knives: 24

- Slitting Configurations: Shear, crush, and Razor

- Web Speed: 100 – 1000 FPM (30.5 – 305 MPM)

- Input Power: 20 AMP 110-230V AC, 1ph

- Position Accuracy: +/- .005” (0.12mm)

Brochure

Related Products

DSE-45 Wideband Ultrasonic Sensor

A high-precision wide band ultrasonic sensor that delivers reliable and accurate measurements in a variety of industrial applications.

DSE-23

A high-precision ultrasonic sensor that delivers reliable and accurate measurements in a variety of industrial applications.

DSE-41 Digital Ultrasonic Sensor

A high-precision ultrasonic sensor that delivers reliable and accurate measurements in a variety of industrial applications.

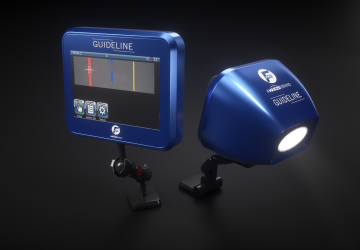

GuideLine & Guideline High Resolution (HR) Digital Line Guide Sensor Overview

Detect lines, edges of lines, graphic patterns, and more where traditional line sensors don’t work at a competitive price point. The GuideLine is suitable for the most demanding line guide applications.

DSE-17 Digital Wideband Infrared Sensor

Most suitable for applications where opacity or density variations may occur, it can track up to 4 independent web edges simultaneously. The DSE-17 sensor eliminates the need for manual repositioning of the sensor, removing moving parts and reducing maintenance and downtime.

DSE-11 Digital Infrared Sensor

The DSE-11 is the smallest infrared sensor available from Fife. It’s compact, lightweight, and insensitive to ambient light, making it ideal for many applications where accurate web guiding is required and space is limited.

DSE-15 Reflected Light Sensor

The DSE-15 is compact and ideal for most applications where space is limited with opaque, transparent, or reflective materials.