Edge-Trim

Designed for trim changes and blade replacements “on the fly” – reducing downtime and waste

Built tough for reliable operations in rugged environments

Automatically maintains critical blade-to-anvil relationship, greatly reducing setup time while ensuring trimming accuracy

Edge-Trim Overview

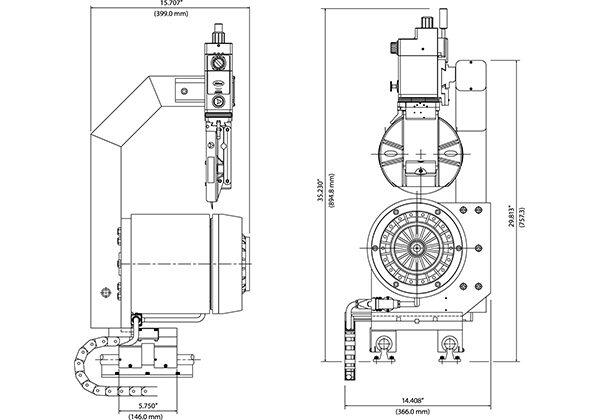

Reduce waste and increase productivity with Tidland’s Edge-Trim, a self-contained shear slitting unit for continuously moving flexible webs. Blade setup time is virtually eliminated during trim changes by quickly repositioning the knife pair (upper and lower blades) simultaneously, without disturbing the slit geometry to maintain the highest level of trim quality.

Edge-Trim - Automated Version

| Simplified Connections | Requires only 110 (or 220) VAC single-phase power and two |

|---|---|

| Touch Screen | Industrial touch screen PC |

| Actuator Control | Lead screw actuator with stepper motor |

| Control Console | Compact and rugged control console enables many mounting options |

| Anvil Motors | Ziehl-Abegg 3-phase External-Rotor-AC dust sealed motors enable |

Edge-Trim - Automated or Manual Version

| Construction | Heavy duty steel construction with non-corrosive nickel plated finish |

|---|---|

| Knifeholders | Performance Series Class II and Class III |

| Carriage | Modular mounts (bottom and back mount available), linear bearings, |

| Trim Widths | Standard trim support 142.2 mm (narrower and wider supports are available) |

| Remote Positioning | Optional lead screw and handwheel with mechanical readout (manual version only) |

- Battery

- Cardboard

- Flexible Packaging

- Food and Beverage

- Nonwovens

- Packaging

- Pharmaceutical

- Specialty Converting

- Tag and Label

- Towel and Tissue

Related Products

Cygnus Tension Controller

The Cygnus Tension Controller is an advanced, intuitive tension controller in a compact enclosure that's easy to navigate for operators.

SE-46C Digital Line Guide Sensor

Detect lines, line edges, graphic patterns and more, where traditional sensors won’t work. Featuring a color touch screen, the image of the web is displayed in full color, for easy and intuitive sensor calibration. The SE-46C is suitable for the most demanding line guiding applications.

External Element Air Shafts

Our External Element Shafts feature innovative two-piece expanding elements for an impressive combination of balance and torque, as well as self-retraction, durable poly bladder, and a fail-safe multi-circuit air system.

Webex Bowed Rolls

Bowed Rolls from Maxcess provide even tension and vibration-free operation for web separation and wrinkle elimination.