H3333 Capacitance Detector

The H3333 Capacitance Detector is a robust and reliable solution for precision web guiding. Designed for conductive strip applications, it features maintenance-free operation, superior accuracy, and easy installation. Ideal for industries like galvanizing, painting, and tin plating.

- Maintenance-free operation with no field calibration required

- Immune to passline, tilt, and edge variations

- Supports ferrous and non-ferrous conductive materials

- Advanced self-diagnostics for consistent performance

Introducing the Fife H3333 Capacitance Detector

The Fife H3333 Capacitance Detector sets a new standard in edge detection technology with its capacitance-based design. This advanced detector offers superior immunity to strip passline changes, tilt, and wavy edges, ensuring precise and reliable performance. Designed for simplicity, the H3333 requires no field calibration and is virtually maintenance-free. Its robust construction makes it ideal for high-activity environments, while its advanced signal processing eliminates the need for manual adjustments. Whether it’s handling occasional moisture or dealing with large strip-width variations, the H3333 delivers consistent results with ease.

Features of the H3333 Capacitance Detector

Engineered for efficiency and reliability, the Fife H3333 boasts key features that make it a superior choice for industrial edge detection. These include:

Low Maintenance: Virtually maintenance-free operation with no field calibration required

High Precision: Tolerates large strip-width variations with minimal impact on the guide point

Durability: Designed to operate in harsh conditions, with models supporting ambient temperatures up to 392°F (200°C)

Easy Integration: Modular assembly allows installation without cutting or removing strips

Broad Compatibility: Suitable for both ferrous and non-ferrous metals and retrofit applications, replacing optical detectors

The Fifie H3333 provides unmatched value and performance, making it a trusted solution for demanding industrial environments.

Applications for the H3333 Capacitance Detector

The H3333 Capacitance Detector is engineered for various industrial applications requiring precise web guiding. Its versatility, durability, and ease of integration make it ideal for the following uses:

Galvanizing Lines: Ensures accurate web positioning during metal coating processes, minimizing defects.

Painting Lines: Provides precise web alignment for smooth, even coating applications.

Tin Plating Lines: Delivers reliable guidance for achieving consistent and high-quality plating results.

Pickle Lines: Performs effectively in corrosive environments, maintaining precision even under challenging conditions.

Optical System Retrofits: Replaces traditional optical detectors with a low-maintenance, more reliable solution for conductive strip detection.

Whether you’re managing ferrous or non-ferrous conductive materials, the H3333 is built to handle demanding environments easily.

Installation Made Simple for the H3333 Capacitance Detector

The H3333 Capacitance Detector is designed for effortless integration into existing systems, ensuring minimal downtime and maximum efficiency during setup.

Module Design: Allows for installation without cutting or removing the strip, making it ideal for retrofit applications.

Pushbutton Setup: Simplifies configuration with a single step to establish the zero-point calibration.

Shielded Construction: Ensures reliable operation even in areas with high operator activity or nearby machinery.

Flexible Placement: Suitable for various process lines, including those with significant strip-width variations or wavy edges.

H3333A vs. H3333E: Choose the appropriate model based on your operating temperature requirements for seamless integration.

With its plug-and-play capabilities, the H3333 minimizes installation complexities, helping your operation get up and running with precision web guiding faster.

- Housing: Anodized structural aluminum

- Operating temperature:

- H3333A: 32-130 F (0-55 C)

- H3333E: 32-392 F (0-200 C), Electronic enclosure limited to 130 F (55 C)

- Guidepoint shift due to passline variation: Less than 0.02” per inch of passline change

- Guidepoint shift due to strip width variation: Less than 0.01” per inch of width change

- Power supply: ± 14.25 to ± 15.75 V dc at 200 mA max

- Outputs:

- Edge 1: ± 10 V dc

- Edge 2: ± 10 V dc

- Edge 1 – Edge 2: ± 10 V dc

- Output impedance: 100 ohms

- Frequency response: dc to 10 Hz

- Output sensitivity: 0.35 V per inch nominal

- Alarm relay output: 2 amp at 24 V ac/dc

Other Resources

Related Products

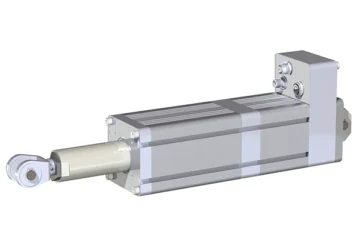

Fife SmartDrive Actuator

The Fife SmartDrive Actuator is an easy to install solution for automated edge and center guiding in converting, laminating, and printing applications.

DST-1 Object Recognition Sensor

The DST-1 offers a revolutionary breakthrough in sensor technology to easily guide an array of materials, from mesh to wire gauge and frayed materials. Using a combination of cameras, infrared lighting, and other sensors, make guiding any material possible with precise positioning.

H3662 Line Scan Sensor

The H3662 is an edge, centerline, or width-detecting IR sensor. Using IR light, it illuminates retro-reflective tape to image onto a linear array within the sensor and, using an integrated microcontroller, it analyzes the array signal and detects the exact position of the web’s edges.

H3218 Center-Guide Detector

As an ideal solution for center-guiding strips in metals applications, the H3218 maintains control during material width changes with no repositioning required during product width changes.