Reliable Service and Support for the Tire & Rubber Industry

At Maxcess, we are dedicated to keeping your tire and rubber operations running at peak performance. With a global network of service centers and expert teams, we offer specialized repair, retooling, and support services to ensure your equipment meets the rigorous demands of your production process.

Guiding & Fabric Spreading Solutions

Tires and rubber production require different rubber webs processed on different production machines. Our guiding & fabric-spreading solutions ensure the end result is produced to meet the most stringent requirements of the tire and rubber industry by feeding the rubber webs into processing with high positional accuracy.

- Controllers

- Actuators

- Sensors

- Guides and Spreaders

Guiding & Fabric Spreading Products

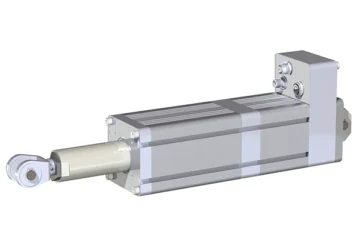

Siłownik Fife SmartDrive

Siłownik Fife SmartDrive to łatwe w instalacji rozwiązanie do automatycznego prowadzenia krawędzi i środka w zastosowaniach związanych z konwertowaniem, laminowaniem i drukowaniem.

Prowadnica liniowa LRC

A precision pivot guide that allows for precise and reliable control in a variety of industrial applications.

Tire & Rubber

H5535

A high-performance actuator with versatile functionality that is suitable for a variety of industrial applications.

Tire & Rubber

Tire & Rubber

Tire & Rubber

Tire & Rubber

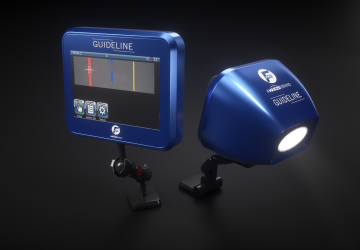

Cyfrowy czujnik liniowy GuideLine

Tire & Rubber

Tire & Rubber

Tire & Rubber

Tension Control Solutions

The MAGPOWR tension control solutions from Maxcess help you achieve defect-free products by identifying and minimizing deviations throughout the production process. Our products will provide you with greater consistency, product quality, and minimal downtime.

- Tension Controllers and Amplifiers

- Brakes

- Load Cells

Tension Control Products

Tire & Rubber

Tire & Rubber

Tire & Rubber

Tire & Rubber

Tire & Rubber

Tire & Rubber

Precision Roll Solutions

The specialized precision roll solutions by Maxcess offer precise and consistent tire and rubber manufacturing, ensuring uniformity in thickness, surface finish, and the alignment of rubber components. All of these elements contribute to producing high-quality products with superior performance characteristics that will meet the stringent tire and rubber industry standards.

- Maxcess Precision Rolls

Precision Roll Products

Tire & Rubber

Tire & Rubber

Tire & Rubber

Slitting and Winding Solutions

The tire and rubber industry requires materials to be cut and wound based on precise dimensions and configurations. Our precision-engineered slitting machines are equipped with sharp blades to cut rubber sheets, belts, and other materials to specific widths with high accuracy. The winding equipment then works to carefully roll or spool the cut material onto cores or reels, creating uniform tension and alignment throughout. The Maxcess slitting and winding solutions help optimize material usage, minimize waste, and enhance production efficiency.

- Slitting and Winding Solutions

Tire & Rubber

Tire & Rubber

Advanced Solutions for Unmatched Tire and Rubber Performance

Discover more about our parts and service solutions for every stage of the tire and rubber process in our helpful guide.

Download Our Tire & Rubber Solutions GuideContact a Maxcess Tire & Rubber Manufacturing Expert

To learn how Maxcess’s line of products and services can enhance and optimize your rubber manufacturing operations, contact a Maxcess representative today.