Product Subcategories

Safety Chucks

Ensure operator safety and maintain efficiency with high-grade safety chucks for effective unwind and rewind applications with minimal setup time.

Monitoring

Wickelwellen und Spannköpfe

Standardkernwellen

Friktionswelle

Mill-Duty Blattwellen und Tamboure

Spannköpfe und Klapplager

Alle Winding Systems and Accessories Produkte

560PM Große Spreizdornwelle

Reduce vibration, operate at higher speeds and greatly expand your productivity. The 560PM from Tidland features a large expansion range, mechanical core centering and improved strength.

D6X Friktionswelle

Lightning-fast bladder changes meet unrivaled price performance for increased uptime and throughput. The D6X is the next generation of core-slip winding technology from Tidland.

PressureMax

Reduce operating costs by minimizing unplanned downtime and scrap while improving safety during unwind and rewind processes with Tidland’s PressureMax system.

GX Ultra Lightweight – Spannwelle

Made with lightweight, high-strength aluminum and innovatie 2-piece expanding element, the Ultra-Light GX Air Shaft delivers unmatched performance in many unwind and rewind applications.

Ultrashaft Kohlefaser Spannwelle

Tidland’s Ultrashaft Carbon Fiber Air Shafts are customizable and offer the perfect combination of durability and high-speed operation in a lightweight, ergonomic air shaft.

Leichtbau-Spannköpfe Force5

The Force5 is incredibly durable in extreme conditions, retains its shape over time and is lightweight, making it an excellent alternative to aluminum chucks at the lowest market cost.

Cyclone™ Hochgeschwindigkeits-Zentrierwelle

The Tidland Cyclone™ Series high speed centering shafts increase throughput by eliminating roll loping and enabling web handling operations to run smoothly at higher speeds of up to 5X faster.

Lug-Wellen

Tidland Lug Shafts are strong and versatile, delivering superior performance in the widest range of converting applications. Eliminate core damage, prevent roll slippage through fast startups and shutdowns and minimize vibration at high web speeds.

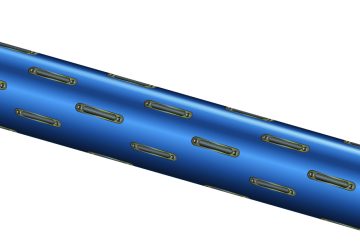

Leaf-Wellen

Ideal for the elimination of thin wall core deformation, leaf shafts are designed for a wide range of converting applications and delicate materials in particular.

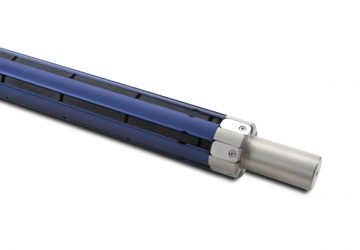

Pneumatische Wellen mit außen liegenden Spannelementen

Our External Element Shafts feature innovative two-piece expanding elements for an impressive combination of balance and torque, as well as self-retraction, durable poly bladder, and a fail-safe multi-circuit air system.

Groß-Expansionswelle

Tidland’s Great-Expansion Shaft is specifically designed for ID core variation changes, allowing for core diameter adjustments while it remains on the machine.

D490 Differentialwelle

Hold rolls straight and true and determine how the shaft engages the core to best suit the material and core you run for improved finished roll quality, reduced scrap and fast, easy setup for even the most sensitive materials.

Tamboure von Tidland

The Series 860 is a heavy-duty air shaft designed for maximum reliability and performance in demanding mill environments, reducing the cost and storage of expensive reel spool mandrels. The ergonomic design also provides increased safety, eliminating the need for locking collars or wrenches.

Mill-Duty Blattwellen

Designed for heavy-duty ID cores and coreless operations, the Tidland Mill-Duty Leaf Shaft is excellent for tougher jobs, providing successful roll control and eliminating thin wall core deformation.

Pneumatische Spannköpfe

Achieve a reliable, no-slip grip that delivers maximum roll control and allows machines to run at maximum speed with rugged, high-torque air chucks.

Spannköpfe der Raptor-Serie

Tidland's Raptor Series Air Powered Lug Chucks are easy to use and maintain, helping eliminate core damage usually associated with shaftless applications.