Reliable Service and Support for the Tire & Rubber Industry

At Maxcess, we are dedicated to keeping your tire and rubber operations running at peak performance. With a global network of service centers and expert teams, we offer specialized repair, retooling, and support services to ensure your equipment meets the rigorous demands of your production process.

Guiding & Fabric Spreading Solutions

Tires and rubber production require different rubber webs processed on different production machines. Our guiding & fabric-spreading solutions ensure the end result is produced to meet the most stringent requirements of the tire and rubber industry by feeding the rubber webs into processing with high positional accuracy.

- Controllers

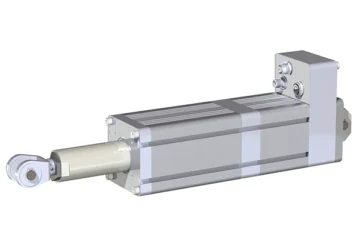

- Actuators

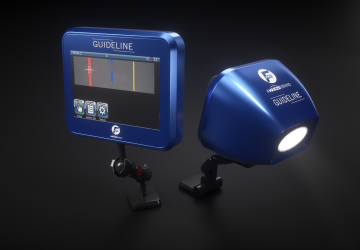

- Sensors

- Guides and Spreaders

Guiding & Fabric Spreading Products

Fife SmartDrive-Antrieb

Der Fife SmartDrive-Aktuator ist eine einfach zu installierende Lösung zur automatischen Kanten- und Mittenführung bei Umwandlungs-, Laminier- und Druckanwendungen.

LRC Offset Pivot Guide

A precision pivot guide that allows for precise and reliable control in a variety of industrial applications.

D-MAX-E-Bahnlaufregler

A compact and easy-to-use web guide controller that offers precise and reliable control for a variety of industrial applications.

H5535

A high-performance actuator with versatile functionality that is suitable for a variety of industrial applications.

Kamberoller Steering Guide Systems

Durable and reliable steering guide systems that provide precise control for a variety of industrial applications.

Simplex H6421 Controller

A high-performance controller that provides precise and reliable control for a variety of industrial applications.

H6630EM Controller

A versatile and easy-to-use controller that provides precise and reliable control for a variety of industrial applications.

DST-1 Objekt-Erkennungssensor

GuideLine Digitaler Bahnlauf-Führungssensor

H3662 Zeilenkopfsensor

Tire & Rubber

Global Maxcess Actuators (GMA)

Tension Control Solutions

The MAGPOWR tension control solutions from Maxcess help you achieve defect-free products by identifying and minimizing deviations throughout the production process. Our products will provide you with greater consistency, product quality, and minimal downtime.

- Tension Controllers and Amplifiers

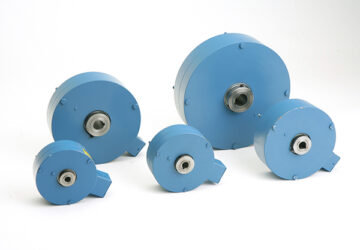

- Brakes

- Load Cells

Tension Control Products

Cygnus Bahnzugregelung

The Cygnus Tension Controller is an advanced, intuitive tension controller in a compact enclosure that's easy to navigate for operators.

MAGPOWR GB Magnetpulverbremsen der Global-Serie

MAGPOWR’s Global Series Magnetic Particle Brakes offer versatility and flexibility, providing a smooth, repeatable, controllable torque independent of speed, suitable for all types of power transmission and tensioning applications.

Tension Amplifiers

Our DLCA and DLCA-NET Digital Load Cell Amplifiers provide powerful and versatile amplification in a compact enclosure, are easy to use and offer weightless load cell calibration for quick setup times.

TS Kraftaufnehmer

TS load cells provide the most consistent tension control regardless of temperature changes. They’re rugged and highly accurate, measuring tension in any unwind, rewind or intermediate web processing application.

MAGPOWR CL Kraftaufnehmer mit einseitiger Lagerung

The CL Cantilevered Load Cells by MAGPOWR are the most cost-effective on the market, with the unique ability to accept virtually any roll and shaft assembly.

MAGPOWR HEB250 Pneumatikbremse

The MAGPOWR HEB250 High Efficiency Brake is a pneumatic tension control brake, ideal for the demands of general converting and corrugating operations, producing higher torque at cooler brake pad temperatures for durability and minimized downtime.

Precision Roll Solutions

The specialized precision roll solutions by Maxcess offer precise and consistent tire and rubber manufacturing, ensuring uniformity in thickness, surface finish, and the alignment of rubber components. All of these elements contribute to producing high-quality products with superior performance characteristics that will meet the stringent tire and rubber industry standards.

- Maxcess Precision Rolls

Precision Roll Products

Webex Wärmeübertragungswalzen (Kühlwalzen)

A uniquely engineered internal temperature management system allows for precise temperature control, ensuring consistent, reliable performance in heat transfer applications.

Webex Umlenkwalzen

We offer more than 400 standard configurations and numerous customizable options available for coating, plating, finish, groove patterns, shaft style, and environmental capabilities.

Slitting and Winding Solutions

The tire and rubber industry requires materials to be cut and wound based on precise dimensions and configurations. Our precision-engineered slitting machines are equipped with sharp blades to cut rubber sheets, belts, and other materials to specific widths with high accuracy. The winding equipment then works to carefully roll or spool the cut material onto cores or reels, creating uniform tension and alignment throughout. The Maxcess slitting and winding solutions help optimize material usage, minimize waste, and enhance production efficiency.

- Slitting and Winding Solutions

GX Ultra Lightweight – Spannwelle

Made with lightweight, high-strength aluminum and innovatie 2-piece expanding element, the Ultra-Light GX Air Shaft delivers unmatched performance in many unwind and rewind applications.

Boschert Klapplager

Tidland Boschert Safety Chucks are pre-engineered for roll support and torque transfer in unwind and rewind applications, available in a variety of options depending on the level of safety and automation required.

Advanced Solutions for Unmatched Tire and Rubber Performance

Discover more about our parts and service solutions for every stage of the tire and rubber process in our helpful guide.

Download Our Tire & Rubber Solutions GuideContact a Maxcess Tire & Rubber Manufacturing Expert

To learn how Maxcess’s line of products and services can enhance and optimize your rubber manufacturing operations, contact a Maxcess representative today.