At one time, the answer would have been “No” and everyone would have agreed. In the new converting world we live in, the answer can be both.

This dual concept also applies to the materials and end products our customers are asking us to convert. Some of these products have not changed over the years, but new ones are brought in each day that challenge us to investigate new solution in order to meet demand. As the converting industry expands into new markets, rotary die-cutting continues to develop new processes and features that are allowing converters to better serve their customers. As our customers demand quicker lead times between order date and shipment times, speed is now a requirement that is as important as price. With the quicker deliveries and added converting features now available with rotary engraved cutting dies, converters are beginning to rethink the rotary die-cutting platform. Once considered a process to produce simple tags and labels, rotary die-cutting continues to evolve into what is considered more of a web fabrication process option. Web fabricating involves more than just printing paper labels and rewinding them onto a roll –rotary web fabrication can now create multiple layered parts all in one pass.

The Power of Rotary Engraved Cutting Tools

The Power of Rotary Engraved Cutting Tools

What was once a clear line between the capabilities of flatbed die-cutting versus engraved rotary cutting has become very fuzzy. Flatbed was the go-to option for certain materials, specific shapes or shorter runs. Today’s rotary cutters can be used to cut not only web or roll form products, but are also capable of cutting sheet fed products. With features such as quick change die stations and higher run speeds, rotary converting is now offering a distinct advantage. The benefits also include longer wearing, more cost-effective cutting dies that are manufactured to a much tighter tolerance than steel rule dies.

Rotary engraved cutting tools and equipment carry the outdated stigma of being only for long run tag and label markets. This simply is not true anymore, and investing to expand into either web fabrication or sheet fed rotary-type cutting may now offer more opportunity than ever before. With the continued development of web fabrication diecutting methods, rotary converting is something to seriously consider for gaining new product offerings for your existing customers as well as the expansion into new, profitable markets. Gaskets, wound care, transdermal patches, medical devices, electronic components and filters are examples of products that are commonly being produced on rotary erb/sheet fed equipment today.

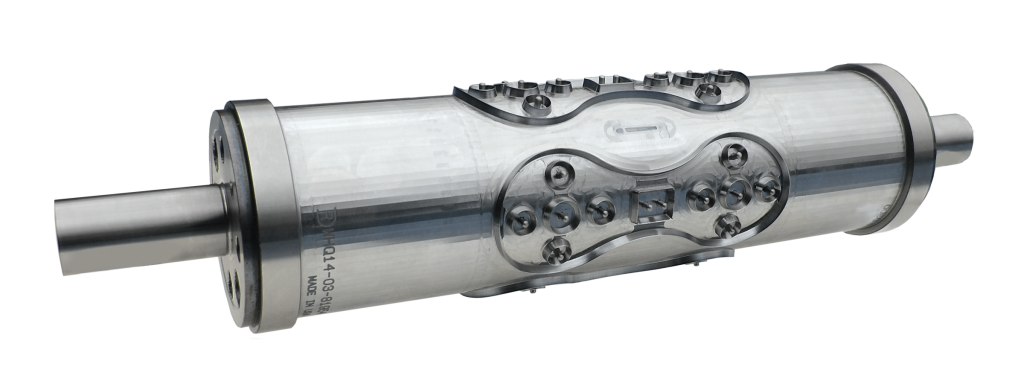

Rotary-based converting equipment offers the ability to run and laminate multiple product layers in line to produce tight tolerance fabricated parts in one pass at reliably higher speeds than ever before. It must be noted that rotary diecutting is not the answer for everything. Due to certain material characteristics and the effect of the rotary knife entering and exiting as it crush cuts the products, material thickness and compressibility play an important role in the results. Many times these challenges can be improved with input from your diemaker. Input such as the diameter of the cutting tool to ensure stability, compound blade angles designed to control part distortion or simple web path processes can play a role in the effort to address these challenges. By working closely with an experience diemaker, these obstacles can be eliminated.

Another example could be very thick, hard materials that can only be cut with the tons of pressure available with a flatbed machine that rotary equipment is not capable of producing. The important point is that there are materials that we use every day that fall between the two extremes mentioned. Rotary engraved diecutters are used every day to produce products from tin, one-layer films or paper to multiple-layer constructions for common medical, automotive and electronic components. Not only are these parts being produced, but it is also being done at higher speeds and tighter tolerances than ever before. An engraved cutting die is limited in run speed only by process itself –the die has no limitations. With a cavity tolerance of +/- 0.001” (0.00254mm), it outperforms steel rule dies in both speed and tolerance every day. These features of speed and accuracy play a huge roll in true costs and, therefore, opportunities.

Not only can rotary-type engraved cutting dies be made to cut to controlled depths with extreme accuracy, they can also be made as thru-cut tools to allow for single parts to be collected at the end of the machine. Converting platforms are available in web fed; roll to roll; or roll to part designs, as well as sheet fed machines made to fabricate parts from single stacked product sheets. In web fabrication markets, the rotary engraved tools offer methods to move or relocate parts on the web. Utilizing air ejection, vacuum or special designed pin ejection methods, slugs and waste can be removed easily and efficiently with this one pass process. Cut the part, strip the waste, remove the slug and rewind or collect –one pass, done! This is being completed at speeds that are unmatched in the flat bed process.

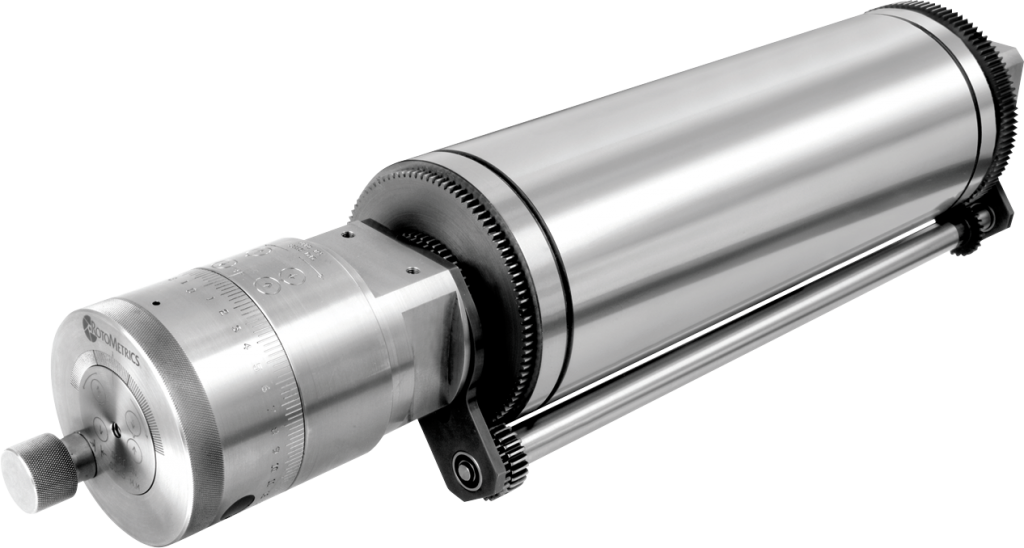

Implications with Anvil Rolls

Rotary diecutting machines are now being designed to allow for removable anvil rolls and cartridge-style dies stations that can be quickly set up and slid in and out of the converting path. The removable anvil feature will open doors to using this bottom roll to form, drive or vacuum parts for removal or replacement. Forming anvil technology continues to grow in design and popularity as converters move into new markets. What was once just a cutting surface now can serve as an important part in the mating of two rolls to create a new product. By having this option available, parts can be diecut not only from the top down, but now also from the bottom up –and in the same station! Tolerance control between these two tools in unmatched, compared to trying to register two steps, two passes or two stations in the manufacturing process.

The Power of Flexible Rotary Dies

The Power of Flexible Rotary Dies

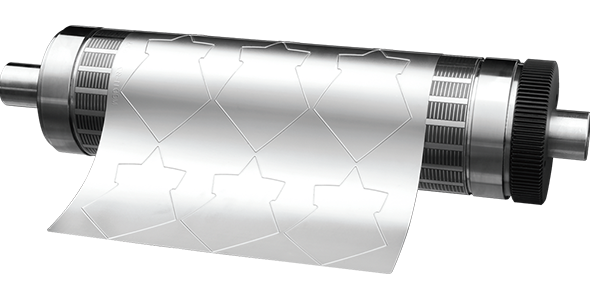

Flexible rotary dies can be an economical option for thinner products. With the use of a rotary magnetic cylinder, converters can purchase high tolerance flexible dies that are quick and easy to change. These tools offer precision cutting results for both paper and film substrates. When tight spacing or small shapes are required, flexible dies can be manufactured and often shipped the next day. This type of tool can ban be an effective alternative to a solid die, offering reduced shipping expense and lower tooling costs. The thin, flexible sheets are hardened and can be chrome-plated to extend die life, making them an attractive option. They are easy to mount and remove from the magnetic cylinder, allowing them to be changed quickly for easy job changes.

It should also be noted that this type of flexible tooling can also be utilized in many flatbed processes. With assistance from your press manufacturer, it may be possible to design a magnetic or wooden counterplate that will allow the use of these tight tolerance plates.

What’s Best for You?

Rotary-type cutting equipment comes in many sizes and designs. Reach out to the leaders of this industry and discuss with them the parts that you hope to manufacture. As with just about anything, machines come in different layouts and pricing levels. But, there is one that will fit your needs.

The same applies to rotary die manufacturers- be sure to choose one that specializes in the tools you need to meet your customers’ expectations. Similar to flatbed/steel rule suppliers, some are more experienced than others in working with certain materials and offer varied features to improve life and cut result.

Choosing the right rotary diemaker is just as important. Work with those who are experienced, with a full product line offering tight tolerance machine finished tools, tools options that may be priced for shorter runs and tools that offer web fabrication features that will make your life easier. Search out the one who offers dedicated support to the non-traditional tag and label markets, who can offer specialty blade angles and profiles to ensure quality cutting results. Look for a supplier who can offer assistance and guidance as you investigate these new opportunities. Could faster speeds and higher tolerance control affect your bottom line? Could rotary converting open new doors? Maybe the world is both round and flat!

If you’d like to learn more about how RotoMetrics can help your business cut the unimaginable quickly and consistently, contact one of our experts.

1 800 325 3851 or find one of our many global locations in your area.

The Power of Flexible Rotary Dies

The Power of Flexible Rotary Dies