IPT Current to Pressure Transducer

- Superior response for control applications

- Compact surface mount design

- Ready to use, no calibration needed

- Operates any pneumatic clutch or brake, regardless of make or size

- Accepts current or voltage control input signal

- Accurate and repeatable

- Multiple mounting options

IPT Current to Pressure Transducer Overview

Space is always at a premium inside working machinery. MAGPOWR knows this well, and therefore constructed its IPT Current or Voltage to Pressure Transducer as a single-manifold design to surface mount inside a machine enclosure. It is designed to be mounted in any orientation with no affect on performance and offers multiple mounting options. The IPT can be mounted on standoffs through four provided mounting holes, or on a DIN 35 rail using the provided mounting clips, or in a customer supplied DIN 35 Modular Circuit Housing.

Perfect for control applications, the IPT is ready to use right out of the box, requiring no calibration and providing superior response, accuracy, and flow characteristics. Versatile and easy to use, the IPT is an ultra-compact PC board level pressure controller that operates on 115/230 VAC and filtered dry shop air, and can accept either a current or voltage control input signal.

| Output | 0 to 80 psi0 to 80 psi |

|---|---|

| Power Input | 115/230 VAC ± 10%, 50/60 Hz switch selectable, 6 VA115/230 VAC ± 10%, 50/60 Hz switch selectable, 6 VA |

| Control Input | 4 to 20 mADC, 249 Ω impedance or 0 to 10 VDC, 10 kΩ impedance4 to 20 mADC, 249 Ω impedance or 0 to 10 VDC, 10 kΩ impedance |

| Linearity, Hysteresis and Repeatability | 0.5% of full scale0.5% of full scale |

| Flow Rate | 3 scfm3 scfm |

| Minimum Supply Air Pressure | Greater than maximum desired outputGreater than maximum desired output |

| Maximum Supply Air Pressure | 150 psi150 psi |

| Operating Temperature | 32 to 104˚ F0 to 40˚ C |

| Storage Temperature | -22 to 176˚ F-30 to 80˚ C |

| Pneumatic Ports | (3) 1/8 NPT threaded ports(3) 1/8 NPT threaded ports |

Featured Products

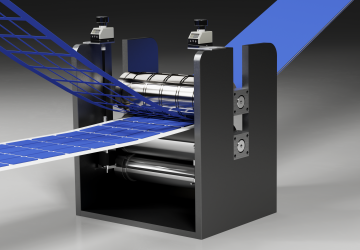

RotoAdjust Dual Adjustable Anvil

The new RotoAdjust offers state-of-the-art Industry 4.0 automation and data analytics to run better, faster, and smarter. Unlock tomorrow’s automation potential today.

AccuAdjust Dual Adjustable Anvil

AccuAdjust solves liner variability issues and allows easy cutting of PET, Glassine, Kraft and more with a simple turn of a precision digital dial. Cut perfect labels and minimize material consumption no matter the liner material.

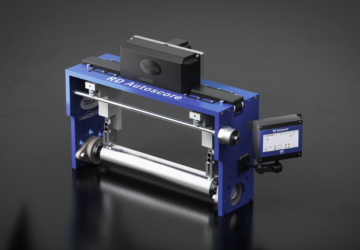

RD AutoScore

Keep operators safe and reduce setup time with the Tidland RD AutoScore system.

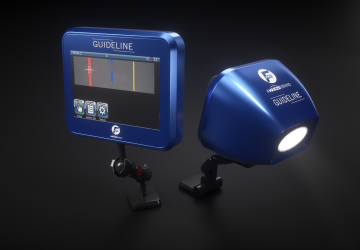

GuideLine & Guideline High Resolution (HR) Digital Line Guide Sensor Overview

Detect lines, edges of lines, graphic patterns, and more where traditional line sensors don’t work at a competitive price point. The GuideLine is suitable for the most demanding line guide applications.