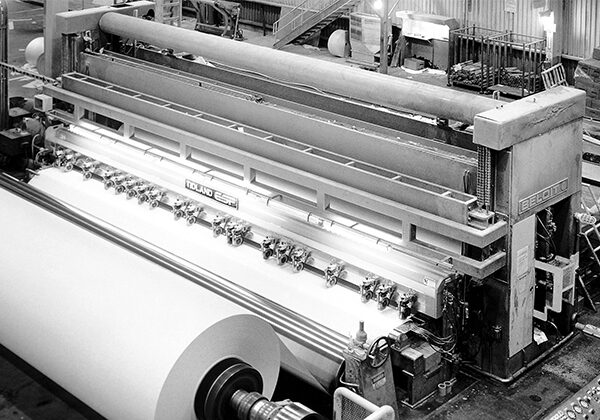

ESP Electronic Slitter Positioning System

Designed to reduce downtime and increase productivity

Can reposition knives in under one minute with accuracy of +/-0.1 mm deviation

Ideal for use in mill finishing and other large-scale converting applications

Electronic Slitter Positioning System Overview

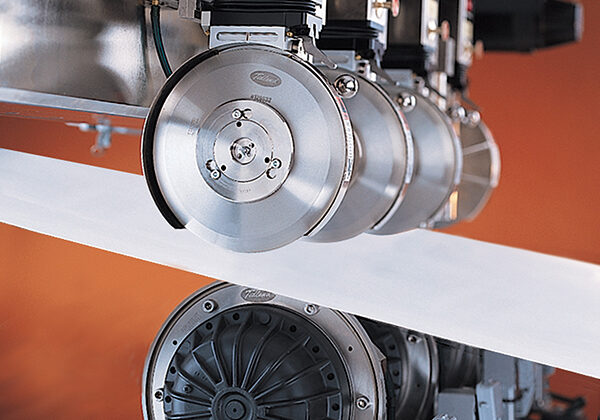

Designed to save downtime and increase productivity, Tidland’s ESP Electronic Slitter Positioning System allows an operator to move 10 knives in under one minute with the web in place, with an accuracy of +/- 0.1 mm (0.004 in) deviation.

Created for use in mill finishing and other large-scale converting operations, the ESP delivers intuitive, easy-to-use touch screen interfaces and can retrofit to most winders regardless of web path. Typical materials include: coated and uncoated boards, tissue, newsprint and fine papers. This robust system has been specifically designed to perform reliably in the most demanding environments.

*Dependent on material and application

ESP Electronic Slitter Positioning System - Class III

| Minimum Slit Width | 6.00 in152.4 mm |

|---|---|

| Maximum Designated Speed* | 3,048 mpm3,048 mpm |

| Pneumatic Instrument Grade Air (Nominal) | 80 - 100 psi80 - 100 psi |

| Electrical 3-Phase Standard | 460 VAC460 VAC |

- Battery

- Cardboard

- Flexible Packaging

- Food and Beverage

- Nonwovens

- Packaging

- Pharmaceutical

- Specialty Converting

- Tag and Label

- Towel and Tissue

Related Products

DSE-45 Wideband Ultrasonic Sensor

A high-precision wide band ultrasonic sensor that delivers reliable and accurate measurements in a variety of industrial applications.

Cygnus Tension Controller

The Cygnus Tension Controller is an advanced, intuitive tension controller in a compact enclosure that's easy to navigate for operators.