Control Series Electronic Knifeholders

Control Series Electronic Knifeholders are built to maximize operator safety, productivity, and roll quality. Each electronic model is equipped with an intuitive, easy-to-use, color touchscreen, and the ability to auto-calibrate the side force and blade overlap ensures increased slit accuracy and consistency to reduce excess scrap.

Control Series Electronic Knifeholders by Tidland

Maximize operator safety, productivity and roll quality with Tidland’s newest innovation in slitting. Featuring an LED-backlit touchscreen interface, enhanced durability and available wireless operation, the Control Series offers a dramatic improvement in knifeholder technology.

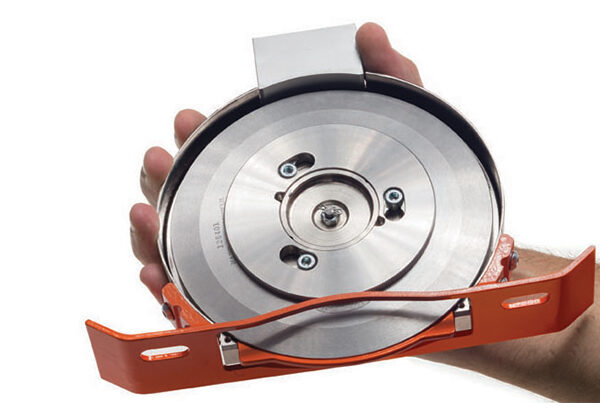

Available in three models, I,II & III, all allow setup in seconds without operator intervention, resulting in increased consistency, less blade wear and reduced downtime between runs. All models are configured with a default 0.035” and include a motorized overlap and side force control with 5 pounds of force (2lbs for Series I). They also have a touch-activated display screen that allows operators to calibrate, engage, and disengage the knifeholder. The installed Tidland 360° Blade Guard Cartridge ensures the blade is fully guarded when the knifeholder is disengaged, and if electrical power fails, the blade will stop and remain in the overlap, side force position.

The Control Plus model adds closed-loop side force control and real-time monitoring via the onboard touchscreen or PC interface so that settings can be confirmed and consistently maintained.

Class I, II & III Control Series Electronic Knifeholders

Despite the difference in size and specific capabilities, the Class II and Class III Control Series Electronic Knifeholders are ideal for converting applications and share similar key features:

- Utilizes a 360° blade guard cartridge

- Minimized operator intervention required for safer slitting operation

- Reduced scrap and increased blade life contributing to lower operating costs

- Self-calibration to reduce the potential for operator error

- Consistent, high-quality slits

- LED-backlit touchscreen for easy programming and monitoring

- Available wireless operation from any WiFi-enabled device (optional)

- Control Plus includes closed-loop side force control and real-time monitoring via onboard touchscreen or optional PC interface

Tidland Control Series Knifeholders Touchscreen

The touch-activated display screen included on the Tidland Control Series Knifeholders allows operators to calibrate, engage, and disengage the knifeholder. Security levels are password protected, allowing the user access to the side force and overlap adjustment capabilities, blade life details, fault history, and other settings. All it takes is a simple tap of the finger on the display to use.

For users needing more advanced control and diagnostics, Maxcess can provide an optional industrial touchscreen PC equipped with proper software for these levels of knifeholder control.

*Dependent upon material and application.

Class I

| Minimum Slit Width | 1 in25.4 |

|---|---|

| Maximum Designated Speed* | 3,500 fpm1,000 mpm *Dependent on material and application |

| Blade Diameter | 3.54 in90 mm |

| Electrical Requirement | 24 VDC24 VDC |

| Auto-Calibrate Accuracy | +/- 0.0005 inch down stroke +/- 0.25 lb side force +/- 0.013 mm down stroke & +/- 0.113 kg side force |

Control Series Electronic Knifeholder - Class II

| Minimum Slit Width | 2.0 in50.8 mm |

|---|---|

| Maximum Designated Speed* | 5,500 fpm1,676 mpm *Dependent on material and application |

| Blade Diameter | 5.91 in150 mm |

| Electrical Requirement | 24 VDC24 VDC |

| Auto-Calibrate Accuracy | +/- 0.5 lbs side force +/- 0.003 in down stroke+/- 0.226 kg side force +/- 0.076 mm down stroke |

Control Series Electronic Knifeholder - Class III

| Minimum Slit Width | 2.95 in75 mm |

|---|---|

| Maximum Designated Speed* | 10,000 fpm3,000 mpm *Dependent on material and application |

| Blade Diameter | 7.87 in200 mm |

| Electrical Requirement | 24 VDC24 VDC |

| Auto-Calibrate Accuracy | +/- 0.5 lbs side force +/- 0.003 in down stroke+/- 0.226 kg side force +/- 0.076 mm down stroke |

User Manuals

Product Sheets

Installation Guide

Brochure

- Tag and Label

- Packaging

- Cardboard

- Food and Beverage

- Flexible Packaging

- Pharmaceutical

- Nonwovens

- Battery

- Towel and Tissue

- Specialty Converting

Related Products

FIFE-500 Web Guiding System

Leverage the latest in web guiding technology and improve efficiency with the cost-effective FIFE-500, ideal for narrow web and nonwoven applications.

Knifeholder Accessories

Safety should be a priority. We offer a wide range of accessories, including safety devices, mounting options and blade guard attachments.

Top and Bottom Slitter Blades, and Slitter Shafts

Blades wear out, need resharpening and need to be refurbished. We know downtime isn’t an option, so choose from our quality replacement slitter blades and rings to get back up and running in no time.

DTR-65 Digital Tension Readout

The DTR-65 offers the ability to have a tension display on a machine panel with the option to also output a tension reference to a drive or PLC to remotely display or control tension.