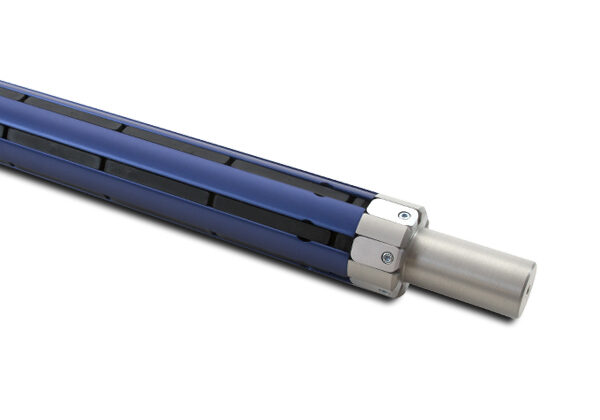

Cyclone High Speed Centering Shaft

Run up to 5X faster

Reduces machine vibration, providing better roll quality and less wear and tear on machine parts

Quick and easy bladder maintenance

Cyclone™ High-Speed Centering Shaft Overview

The Tidland Cyclone™ Series high speed centering shafts increase throughput by eliminating roll loping and enabling web handling operations to run smoothly at higher speeds. In test environments, customers have been able to run up to 5X faster using the Cyclone!

The external element, two-stage pneumatic design holds the core concentric to the body, reducing machine vibration and wear.

The Cyclone Series is available in diameters ranging from 3 inches to over 20 inches.

Cyclone High Speed Centering Shaft - 3 in

| Shaft Diameter | 3.00 in76.2 mm |

|---|---|

| Collapsed | 2.96 in75.1 mm |

| Expanded | 3.15 in80 mm |

Cyclone High Speed Centering Shaft - 6 inch

| Shaft Diameter | 6.00 in152.4 mm |

|---|---|

| Collapsed | 5.96 in151.3 mm |

| Expanded | 6.15 in156.2 mm |

- Battery

- Cardboard

- Flexible Packaging

- Food and Beverage

- Nonwovens

- Packaging

- Pharmaceutical

- Specialty Converting

- Tag and Label

- Towel and Tissue

Related Products

D-MAX OI-TS Operator Interface

User-friendly touchscreen operator interface allowing for easy and intuitive control of web guiding systems in industrial applications.

Control Series Electronic Knifeholders

Maximize operator safety, productivity and roll quality with Tidland’s Control Series. Features include an LED-backlit touchscreen interface, enhanced durability and available wireless operation.

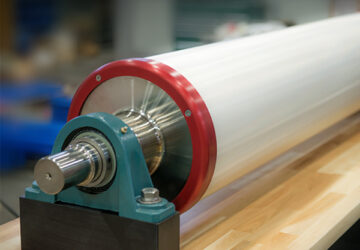

Vacuum Tension Rolls

A uniquely engineered internal vacuum system provides a strong, stable grip on a variety of materials, ensuring consistent and reliable web handling.